Printing technique can form 3D shapes from gel sheets

26 March 2012

A new method for manufacturing three-dimensional shapes from gel sheets easily and cheaply, has applications in biomedicine, robotics and tunable micro-optics.

The method, Developed at the University of Massachusetts Amherst, is inspired by the ability of plants to shape a petal and builds on simple techniques used in photolithography and printing.

Many plants create curves, tubes and other shapes by varying growth in adjacent areas. While some leaf or petal cells expand, other nearby cells do not, and this contrast causes buckling into a variety of shapes, including cones or curly edges. "We wanted to develop a strategy that would allow us to pattern growth with some of the same flexibility that nature does,” says researcher Ryan Hayward.

Hayward and colleagues developed a method for exposing ultraviolet-sensitive thin polymer sheets to patterns of light. The amount of light absorbed at each position on the sheet programs the amount that this region will expand when placed in contact with water, thus mimicking nature’s ability to direct certain cells to grow while suppressing the growth of others. The technique involves spreading a 10-micrometer-thick layer of polymer onto a substrate before exposure.

Areas of the gel exposed to light become crosslinked, restricting their ability to expand, while nearby unexposed areas will swell like a sponge as they absorb water. As in nature, this patterned growth causes the gel to buckle into the desired shape. Unlike in nature, however, these materials can be repeatedly flattened and re-shaped by drying out and rehydrating the sheet.

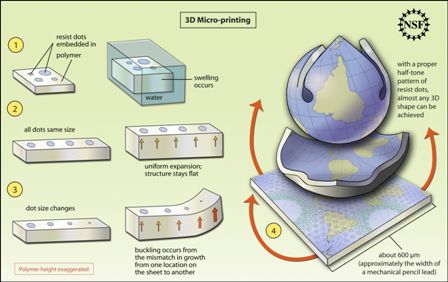

Controlling growth in a polymer system at the

micro-scale with a technique akin to half-tone printing, yhr polymer

swells like a sponge when exposed to water. Printing “resist dots”

in the polymer substrate creates points that will not swell. When

the dot size changes, buckling occurs from the mismatch in growth

from one area to another. With a proper half-tone pattern of resist

dots, almost any 3D shape can be achieved. Credit: Zina Deretsky, NSF

To date, the researchers have made a variety of simple shapes including spheres, saddles and cones, as well as more complex shapes such as minimal surfaces. Creating the latter represents a fundamental challenge that demonstrates basic principles of the method, Hayward says.

He adds, “Analogies to photography and printing are helpful here.” When photographic film is exposed to patterns of light, a chemical pattern is encoded within the film. Later, the film is developed using several solvents that etch the exposed and unexposed regions differently to provide the image we see on the photographic negative. A very similar process is used by UMass Amherst researchers to pattern growth in gel sheets.

Santangelo and Hayward also borrowed an idea from the printing industry that allows them to make complicated patterns in a very simple way. In photolithography, just as in printing, it is expensive to print a picture using different colour shades because each shade requires a different ink. Thus, most high-volume printing relies on halftoning, in which only a few ink colours are used to print varied-sized dots. Smaller dots take up less space and allow more white light to reflect from the paper, so they appear as a lighter colour shade than larger dots.

An important discovery by the UMass Amherst team is that this

concept applies equally well to patterning the growth of their gel

sheets. Rather than trying to make smooth patterns with many

different levels of growth, they were able to simply print dots of

highly restricted growth and vary the dot size to program a

patterned shape. In the image on the right, a buckled gel sheet

shrinks, flattens and then regrows into a patterned

three-dimensional shape driven by changes in temperature.

An important discovery by the UMass Amherst team is that this

concept applies equally well to patterning the growth of their gel

sheets. Rather than trying to make smooth patterns with many

different levels of growth, they were able to simply print dots of

highly restricted growth and vary the dot size to program a

patterned shape. In the image on the right, a buckled gel sheet

shrinks, flattens and then regrows into a patterned

three-dimensional shape driven by changes in temperature.

“We’re discovering new ways to plan or pattern growth in a soft polymer gel that’s spread on a substrate to get any shape you want,” Santangelo says. “By directly transferring the image onto the soft gel with half-tones of light, we direct its growth.”

He adds, “We aren’t sure yet how many shapes we can make this way, but for now it’s exciting to explore and we’re focused on understanding the process better. A model system like this helps us to watch how it unfolds. For biomedicine or bioengineering, one of the questions has been how to create tissues that could help to grow you a new blood vessel or a new organ. We now know a little more about how to go from a flat sheet of cells to a complex organism.”