Sony DADC and Axela to develop smart consumables for immunoassays

25 January 2012

Salzburg, Austria and Toronto, Canada. Sony DADC and Axela have entered into a collaboration to develop and manufacture smart consumables for the dotLab mX detection system.

The dotLab mX System combines automated flow processing with diffractive optics to enable real-time detection of binding events and full characterization of biomarkers through sequential probing. This provides significant analytical advantages for multiplex assay development and routine analysis in clinical research and diagnostics. The resultant dynamic range and panel flexibility is unachievable with any other commercially available product.

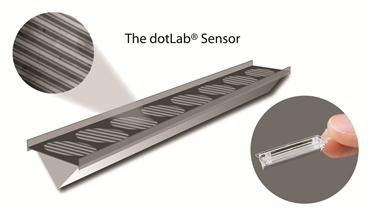

Figure 1: The dotLab sensor employs multiple

micropatterned capture areas in a flow channel to create biological

diffraction gratings. When a specific binding event takes place,

the efficiency of the grating improves proportionately. The signal

is monitored in real time and can be used to determine concentration

and avidity of captured analytes. A wide range of materials can

serve as affinity reagents including antibodies, antigens,

carbohydrates, nucleic acids and intact viruses.

Paul Smith, Axela’s COO said: “Axela products can have an important impact on healthcare by simplifying analysis and significantly cutting the time from sample acquisition to result. Uniquely leveraging real time and label free analysis, this assay platform provides access to new combinations of biomarkers. Partnering on these advanced consumables will accelerate our expansion from research markets into applied testing and diagnostics.”

“Sony DADC BioSciences is excited to translate its excellence in manufacturing microstructured polymer devices like optical discs to the production of the next generation of dotLab® sensors for label free detection of protein biomarkers, bacteria and viruses.” said Harald Kraushaar, VP at Sony DADC.

Jessica Melin, Sr. Manager Business Development and Sales North America commented: “Axela’s demand for high-quality consumables and our manufacturing capabilities are a perfect match. We provide a scalable manufacturing solution based on injection molding that reduces the number of manufacturing steps. Furthermore, our technology will deliver consumables that are compatible with a broader range of applications and instrument formats.”

Axela’s VP of Product Development and Manufacturing, Dr. Alex Izmailov said: “Pairing our innovative platforms with high performance consumables is the key to success. Sony DADC’s precision sensors in combination with the inherent self referencing properties of diffractive optics will make our system highly attractive not only for biomarker screening and assay development but also as the method of choice for robust, routine analysis.”

Source: Sony DADC, Axela