New nanochemistry analytical tool based on quartz crystal

03 Dec 2010

A new chemical analysis technique developed by a research group at the US National Institute of Standards and Technology (NIST) uses the shifting ultrasonic pitch of a small quartz crystal to test the purity of only a few micrograms of material.

Since it works with samples close to a thousand times smaller than comparable commercial instruments, the new technique should be an important addition to the growing arsenal of measurement tools for nanotechnology, according to the NIST team.

As the objects of scientific research have become smaller — eg in nanotechnology and gene therapy — scientists have been applying considerable ingenuity to develop comparable instrumentation. This new NIST technique is based on thermogravimetric analysis (TGA).

In TGA, a sample of material is heated, very slowly and carefully, and changes in its mass are measured as the temperature increases. The technique measures the reaction energy needed to decompose, oxidize, dehydrate, or otherwise chemically change the sample with heat.

TGA can be used, for example, to characterize complex biofuel mixtures because the various components vaporize at different temperatures. The purity of an organic sample can be tested by the shape of a TGA plot because, again, different components will break down or vaporize at different temperatures. Conventional TGA, however, requires samples of several milligrams or more of material, which makes it hard to measure very small, laboratory-scale powder samples — such as nanoparticles — or very small surface chemistry features such as thin films.

What's needed is an extremely sensitive microbalance to measure the minute changes in mass. The NIST group found one in the quartz crystal microbalance. Essentially it is a small piezoelectric disk of quartz sandwiched between two electrodes. An alternating current across the electrodes causes the crystal to vibrate at a stable and precise ultrasonic frequency — the same principle as a quartz crystal watch. Added mass (a microsample) lowers the resonant frequency, which climbs back up as the microsample is heated and breaks down.

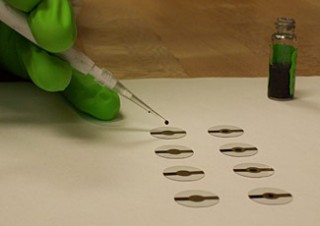

A NIST researcher prepares quartz crystal

microbalance disks with samples of carbon nanotubes for for

microscale thermogravimetric analysis. Typical sample sizes are

about 2 microliters, or about 1 microgram.

In a new paper, the NIST materials science group demonstrates that their microbalance TGA produces essentially the same results as a conventional TGA instrument, but with samples about a thousand times smaller [1]. They can detect not only the characteristic curves for carbon black, aluminium oxide and a sample organic fluid, but also the more complex curves of mixtures.

"We started this work because we wanted to analyze the purity of small carbon nanotube samples," explains analytical chemist Elisabeth Mansfield. More recently, she says, they've applied the technique to measuring the organic surface coatings biologists put on gold nanoparticles to modify them for particular applications. "Measuring how much material coats the particles surface is very hard to do right now," she says, "It will be a really unique application for this technique."

The prototype apparatus requires that the frequency measurements be made in a separate step from the heating. Currently, the team is at work integrating the microbalance disks with a heating element to enable the process to be simultaneous.

Reference

1. E. Mansfield, A. Kar, T.P. Quinn and S.A. Hooker. Quartz crystal microbalances for microscale thermogravimetric analysis. Anal. Chem. Article ASAP, published online Nov. 16, 2010. DOI: 10.1021/ac102030z