Why nanocorrosion causes coated implants to fail

17 August 2010

Extra-hard coatings made from diamond-like carbon (DLC) are used to extend the operating lifetime of tools and components that undergo wear. In artificial joints, however, these coatings often fail and detach.

Researchers at the Swiss organisation Empa have found out that the coatings fail due to corrosion in the reaction layer under the coating. They have developed methods to both make the interface between the DLC layer and the metal underneath corrosion-resistant and to predict the lifetime of the implants.

Extremely hard coatings made of diamond-like carbon (DLC) have proven their value on products such as computer hard disks, saw blades, embossing tools, razor blades and fuel-injection nozzles. They reduce wear and thereby give tools and components a longer operating lifetime. A number of implant manufacturers reasoned that it would be useful to apply DLC to medical implants such as artificial joints, where wear is also a problem.

DLC has subsequently withstood endless in vitro tests in several manufacturers’ laboratories and has shown itself to be well tolerated by human tissue, extremely hard wearing, and resistant to the relatively aggressive environment in the human body. Despite this, when DLC-coated joints were first implanted into human patients, serious problems arose after only a few years. The DLC coatings were not worn away, but rather they detached from the implant material for no apparent reason.

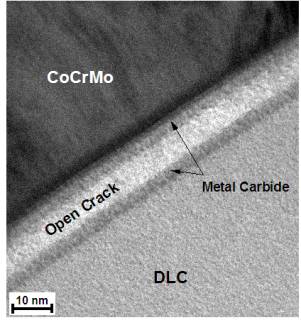

Under physiological conditions, stress corrosion cracking leads to a slow-growing crack in the metal carbide reaction layer, which is barely 5 nanometers wide. This, in turn, causes the DLC layer to detach from the implant material (cobalt-chrome-molybdenum, CoCrMo), as seen in the transmission electron microscope image above.

Targeting the interface

In a project financed by the Swiss Innovation Promotion Agency (CTI) together with the medical technology company Synthes and the coating company Ionbond AG, Empa researchers sought out the cause of this detachment. For this, the researchers conducted detailed studies of the interface between the implant material and the coating.

"When two materials are placed in contact with each other, the result is a reaction layer at the interface between them, which is only several atomic layers thick. Thus a new material is formed, which we investigated now for the first time", explains Roland Hauert of Empa's "Nanoscale Materials Science" laboratory.

His team showed that the so far barely considered reaction layer, which is not always completely corrosion resistant, is responsible for the detachment of the DLC layer. On the one hand, stress corrosion cracking occurred in the reaction layer. The mechanical load in conjunction with the penetration of body fluids led to slow-growing cracks, which in turn caused the DLC substrate to detach little by little.

In other cases, crevice corrosion was responsible for the damage. Over time, an aggressive, acidic medium develops in fine crevices and slowly dissolves the reaction layer or the additional adhesive layer, likewise leading to detachment.

Methods to determine operating lifetime

Together with their industry partners Synthes and Ionbond, Empa developed a corrosion-resistant intermediate layer at the interface to the DLC layer. What's more, the researchers also developed a process that can determine a crack’s growth rate under conditions similar to those experienced in the human body as well as the dissolution rate of the reaction layer in cases of crevice corrosion.

"This then allows us to calculate the expected operating lifetime of the coated implant in the human body", says Roland Hauert. Whether or not a DLC-coated implant will fail prematurely in vivo can henceforth already be determined during the development of the product.