Taking nanotechnology from lab to factory8 February 2008 An EU-funded 'network of excellence' has helped micro and nanotechnology make it from the laboratory to the factory. The Design for Micro & Nano Manufacture (Patent-DfMM) network was granted €6.2m for a 4.5-year project that involved teams from the fields of packaging, test engineering, reliability engineering, simulation and modelling. The project is due to end later this year, but the network is expected to continue by being self-funding.

However,

the development of marketable products lags well behind the scientific

advances. Often the devices only exist in the laboratory as a demonstration.

These prototype lab demonstrations look ugly, but often work and they prove

functionality at the nano- or micro-scale. They also often determine whether

the invention will ever see the light of day. The reason is that up to 80% of

the unit cost for micro- and nano-devices is in the packaging and testing

phase, and the unit cost must often come in under

€1. “Many innovations are just too expensive to commercialise,” notes

Salomon. “We had a lot of control over how we assessed projects for funding within the network,” says Salomon. “As a result, we were able to get quite a significant impact.” In the end, the NoE supported over 60 small-scale projects. These looked at ways to simplify the “design for micro manufacture” process. In essence, researchers learn about manufacturing constraints before starting a design and they take these into account during the concept phase, to optimise units for manufacturing processes. This drives down costs and the time to market. The network funded research into ways of re-using one design, or its building blocks, for a different type of product. It also studied more efficient ways to test for robustness and perform quality control. Already, these projects have had an important impact, though Salomon admits that they are difficult to quantify. The end of the beginning But that’s just the beginning. PATENT-DfMM also conceived a series of service clusters — groups of specialists in particular areas of micro- and nanotechnology, offering services in design for manufacture, testing and reliability. “These target specifically SMEs and can provide help for companies seeking to commercialise a nano- or microtechnology,” notes Salomon. So far, PATENT-DfMM has set up two; one specialised in miniaturised health-monitoring systems (HUMS), while another focuses on reliability (EUMIREL). In all, it offers hope of a commercial life for the thousands of lost innovations gathering dust in labs across the continent, and more importantly, to make sure future inventions are “designed for manufacture” from their initial development phase. For more information on PATENT-DfMM see: www.patent-dfmm.org Source: ICT Results |

Research

into nanotechnology is forging ahead in laboratories around the world. There

are a myriad of applications in areas ranging from cosmetics ingredients to

molecular vehicles for building new compounds. There is plenty of innovation

in micro- and nanotechnologies, but bringing new devices to market is often

prohibitively expensive. Many micro devices have small production volumes,

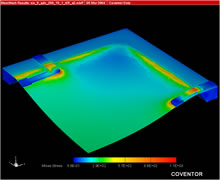

while design, packaging and testing are costly. Under the project, European

researchers have been breaking down the barriers by developing design

methodologies that focus on manufacturing, packaging and testing.

Research

into nanotechnology is forging ahead in laboratories around the world. There

are a myriad of applications in areas ranging from cosmetics ingredients to

molecular vehicles for building new compounds. There is plenty of innovation

in micro- and nanotechnologies, but bringing new devices to market is often

prohibitively expensive. Many micro devices have small production volumes,

while design, packaging and testing are costly. Under the project, European

researchers have been breaking down the barriers by developing design

methodologies that focus on manufacturing, packaging and testing.